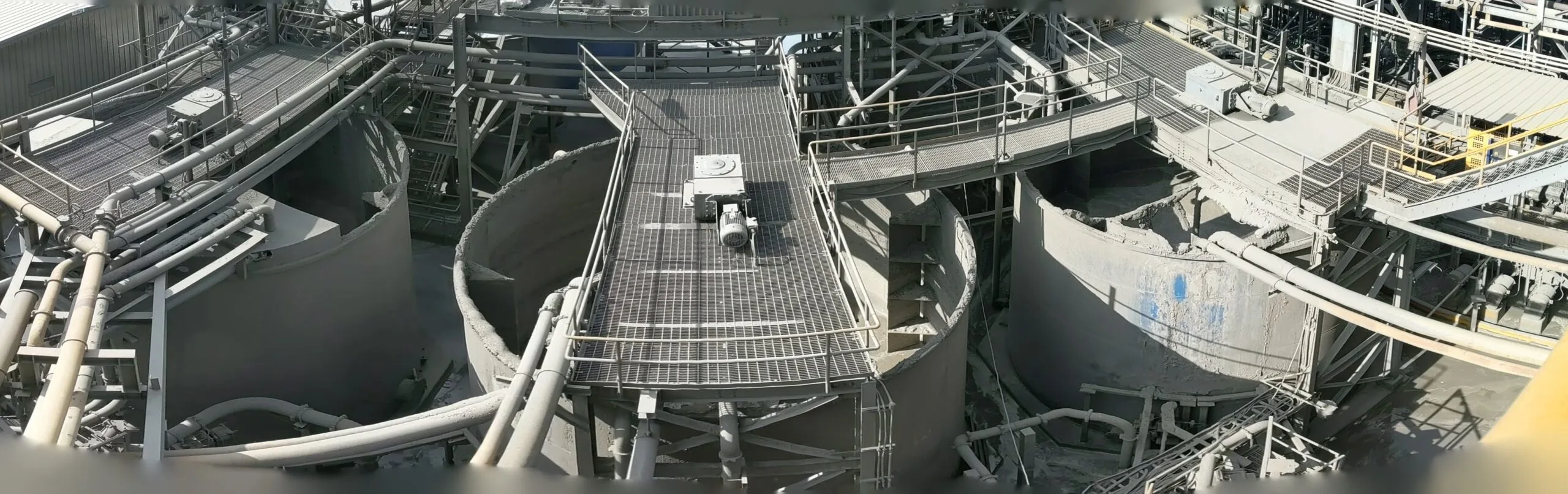

Pyroprocessing & Gas Handling

Efficient thermal processing and gas management are critical to the performance, efficiency, and sustainability of cement, lime, and other minerals plants. At Consultec, we provide pyroprocessing services and gas handling engineering consulting that help clients optimize kiln operation, control emissions, and improve overall plant performance. Our team has extensive pyroprocessing and gas handling expertise, delivering solutions that are practical, reliable, and energy-efficient.

Our Pyroprocessing & Gas Handling expertise includes:

- Kiln, Calciner Design: optimized layouts and equipment selection for thermal efficiency and process stability.

- Combustion System Engineering: solutions for fuel efficiency, reliable operation, and process control.

- Heat Recovery & Energy Optimization: maximizing energy reuse and minimizing operating costs.

- Gas Cleaning & Dust Collection: high-efficiency systems to reduce particulate emissions and meet environmental standards.

- Flue Gas Treatment: advanced solutions for regulatory compliance and sustainable operations.

- Retrofits & Greenfield Projects: upgrades, modernization, and complete plant design support.

Consultec’s engineers bring a practical, field-focused approach to pyroprocessing and gas handling. Whether for new facilities, brownfield upgrades, or plants in remote or extreme environments, our designs focus on delivering reliable, maintainable equipment and systems while optimizing energy efficiency and reducing operating costs. We ensure full compliance with environmental and regulatory requirements and prioritize the long-term sustainability of both operations and surrounding communities.

From feasibility studies to detailed design and construction supervision, Consultec provides complete pyroprocessing and gas handling services for the cement, lime, industrial minerals, and metals industries.