Challenge

Detail Engineering and Procurement services for a new Carbon Preflotation Plant and Tie-Ins.

Process

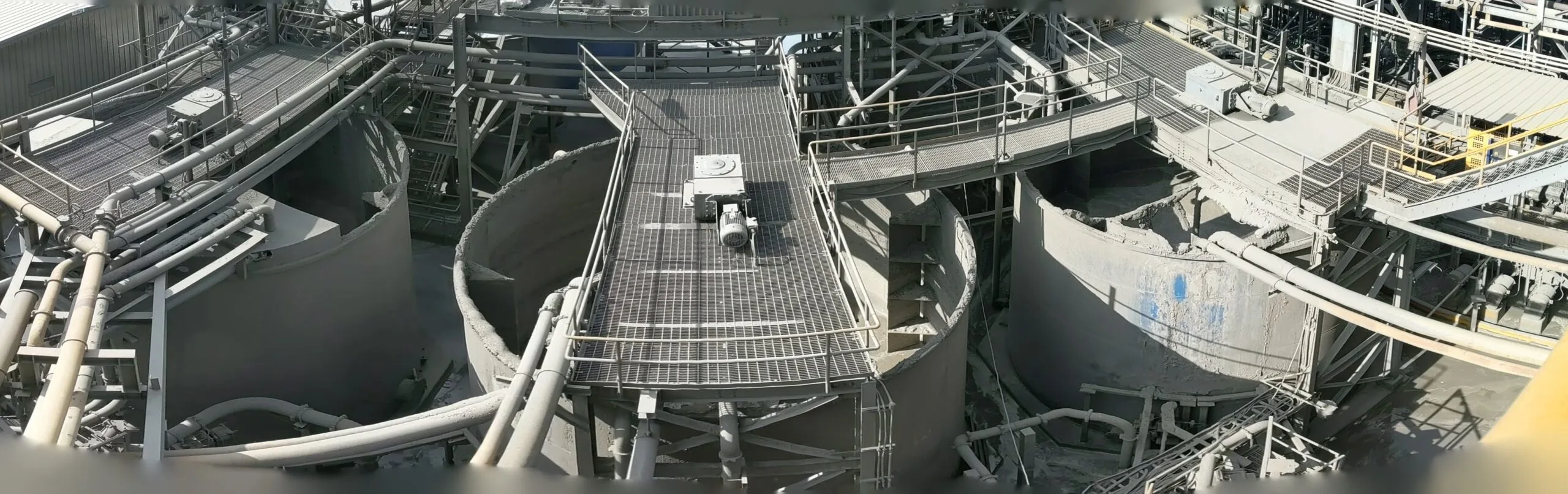

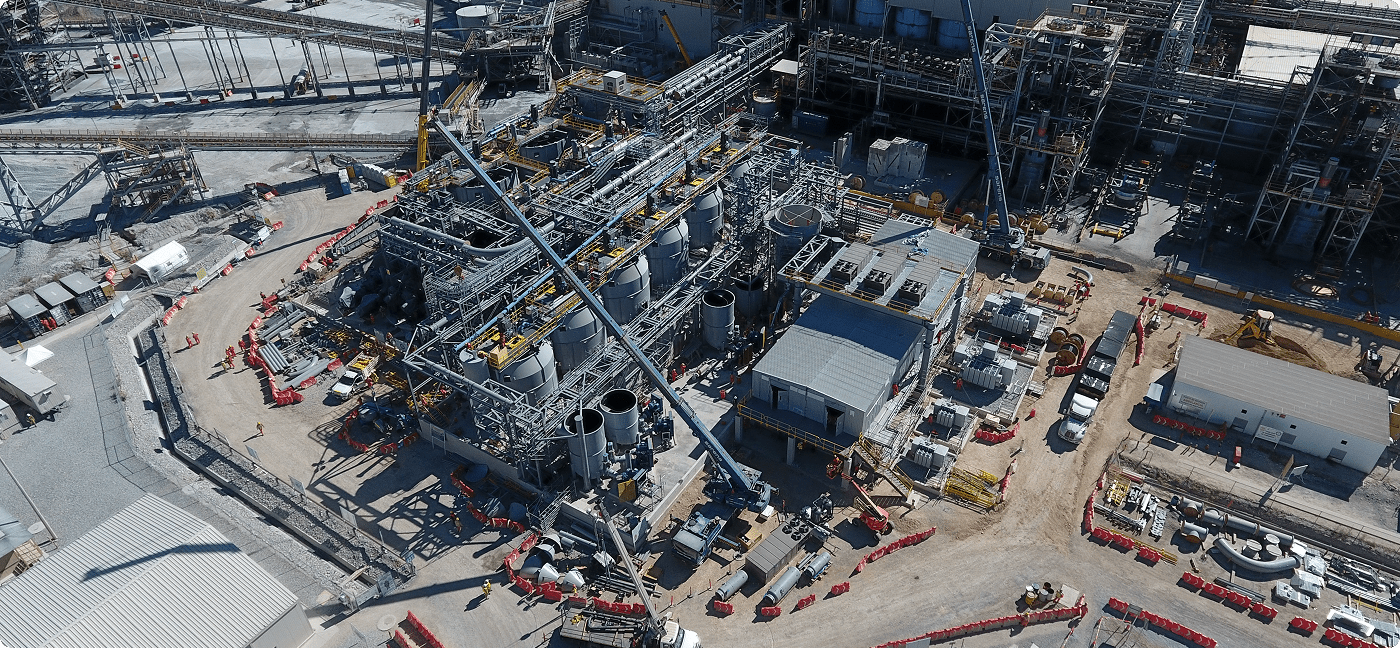

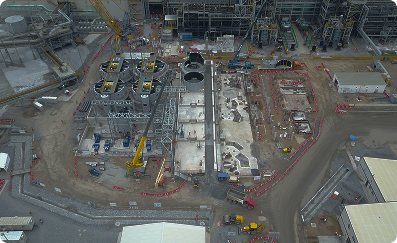

BROWNFIELD project Including: (2) lines of (2) 600m3 Roughers (3) 300m3 Cleaners (3) 300m3 Scavengers Recleaner Column

Delivery

An existing Open Pit mine and processing facility located in Mexico has ore with high levels of carbonaceous material that when processed destabilizes the downstream lead and zinc flotation circuits leading to poor recovery and high operating costs. The project scope included diverting all of the existing plant’s mill feed to a carbon preflotation circuit consisting of roughers, cleaners, cleaner-scavengers and recleaner flotation cells in order to remove the carbonaceous material. The resulting “clean” tailings was pumped back into the existing lead/zinc flotation circuits. Consultec, in partnership with Outotec Canada, designed the plant and procured all equipment, plant services/utilities, and supported all bulk procurement, construction and commissioning activities. Basic + Detail Engineering were completed on a fast-track basis within an 8 month period and constructed/commissioned within 24 months of the start of basic engineering.

| photo |

Explore the Project Gallery