Challenge

An open pit expansion to two underground mines, required a new paste backfill system to produce a cemented backfill used to fill underground stopes. The paste backfill is composed of dewatered mill tailings and slag/cement binder mix that is pumped or allowed to flow by gravity. This part of Canada is both a severe cold climate and remote location for such a project requiring specific design consideration including: precast concrete work, modular design based on shipping dimensions, heat tracing and insulation of piping and bins, building and entry space heating.

Process

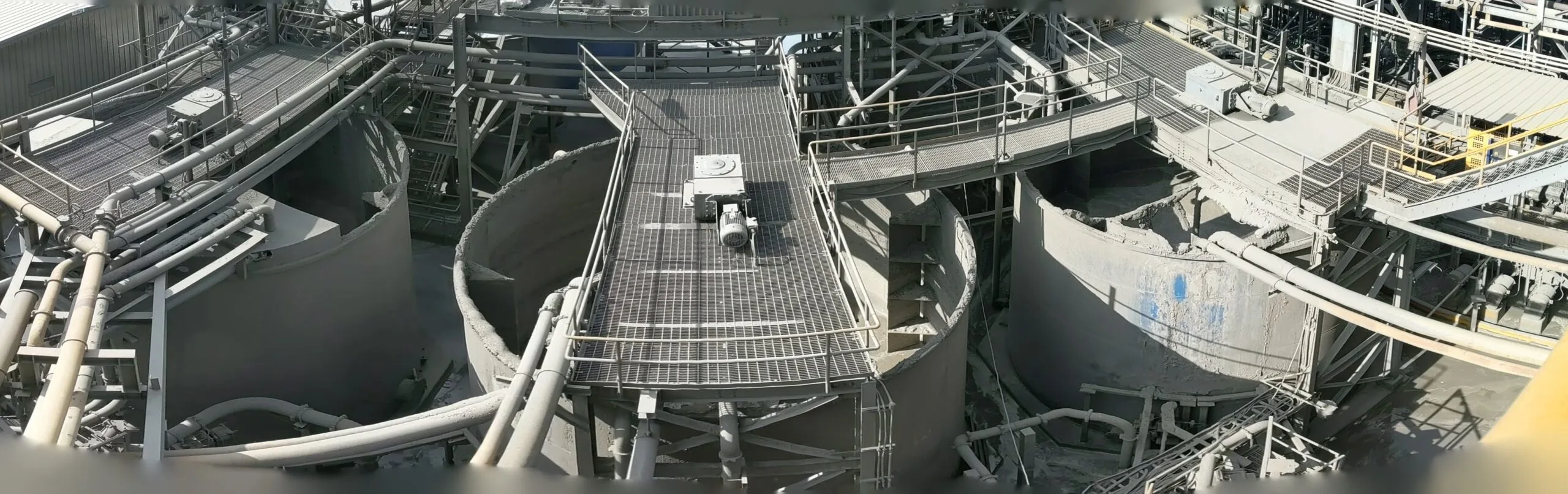

The facility included a 360 t/h paste plant, booster station and binder storage facility.

Delivery

Consultec, in partnership with an equipment supplier, designed the plant and procured the process equipment, plant services/utilities, electrical equipment and construction bulk materials.

| photo |

Explore the Project Gallery