Gold Mine – Brownfield EP

A Brownfield project to recommission a 2500 t/d gold concentrator in a remote location in Northern Canada.

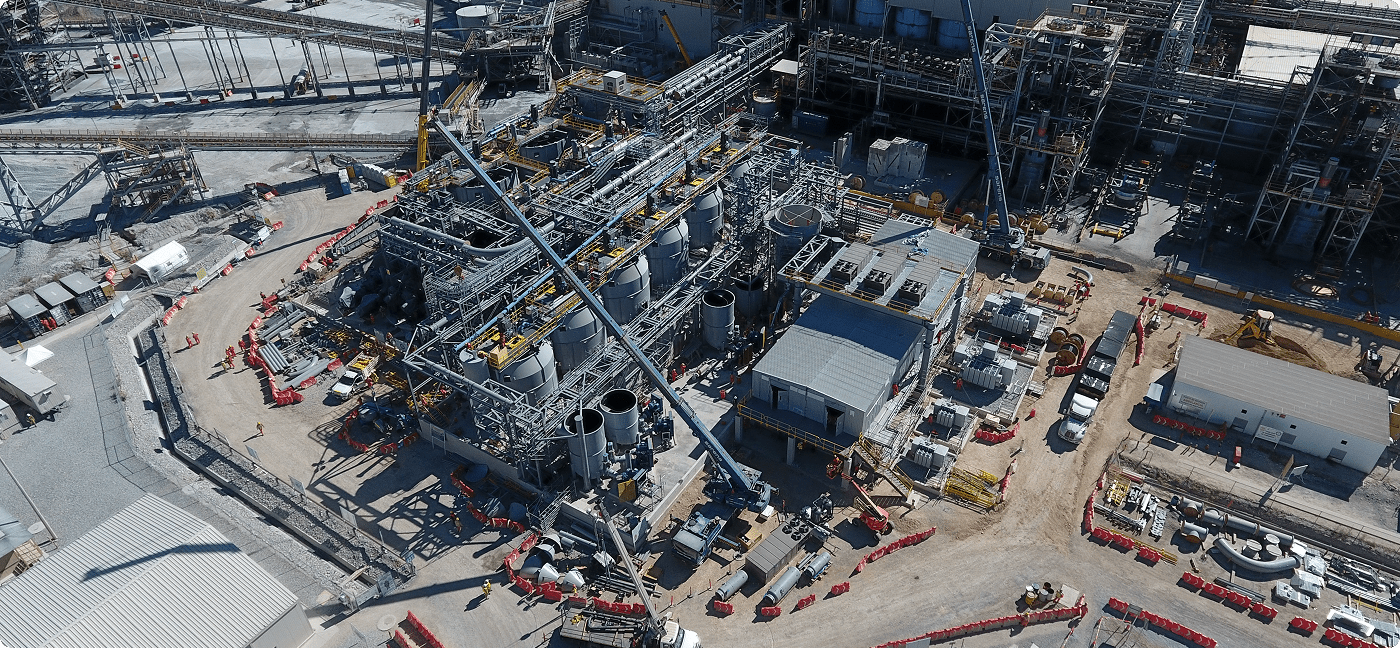

Flotation Plant – Gold

Detail Engineering and Procurement services for a new Carbon Preflotation Plant and Tie-Ins.

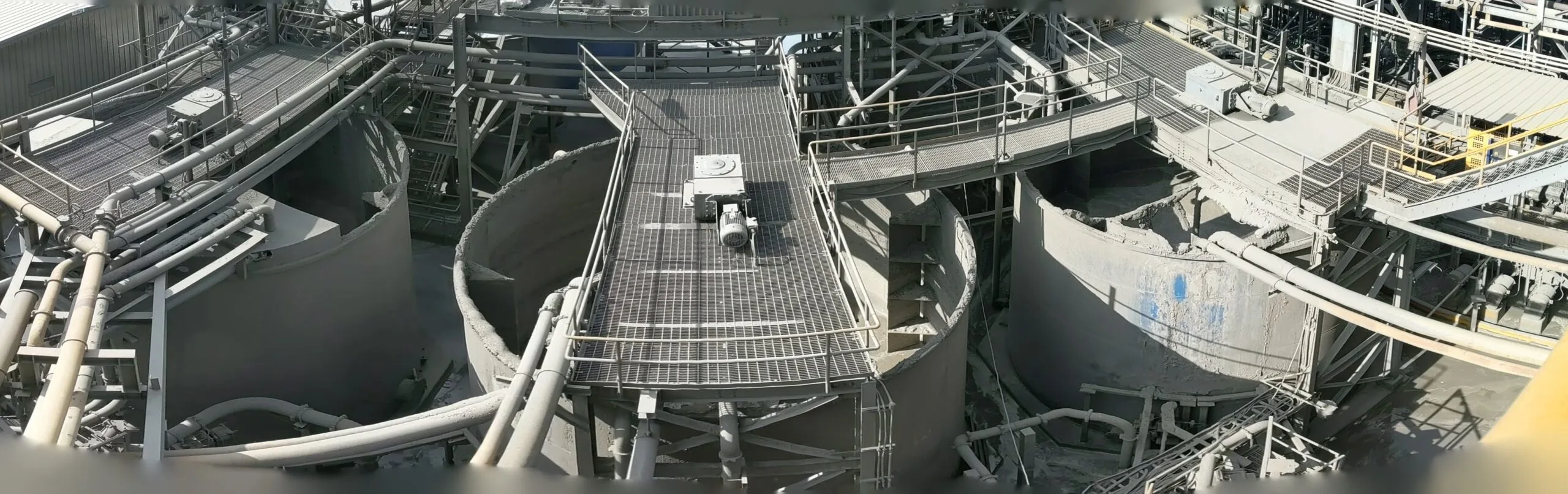

Mine Paste Fill

An open pit expansion to two underground mines, required a new paste backfill system to produce a cemented backfill used to fill underground stopes.

Cement Kiln Line, 3000 t/d

Design and construction supervision of a 3000 t/d clinker kiln line from raw material storage and handling, raw grinding, pyroprocessing and clinker storage.

Waste Fuels

Waste fuels such as agricultural waste and tire chips are an excellent and economic source of replacement fuel to coal.

Rail Terminal – Coal

2 x 30,000T capacity coal silos for rail loading.

Cogeneration Plant – Biomass

A 25 MW cogeneration power plant, fired by waste wood.

Silo – Ecuador

Design and construction supervision of a 70000T capacity clinker storage silo.